Large timber floors

In modern construction, building techniques have been enhanced by the integration of different materials, exploiting the individual strengths of each component. The stiffness of reinforced concrete allows the post-and-slab construction system to be reimagined using a hybrid approach that combines the structural benefits of timber with the strength of concrete.

Definition and features of post-and-slab technology

Post-and-slab technology implies a construction system whereby the vertical components or “posts”, are directly connected to the floors or “slabs”, thus eliminating the use of beams. Using specialised solutions, this approach significantly reduces the number of columns required, allowing for the design of open spaces and multi-storey buildings with expansive interiors.

In these cases, to prevent crushing of the floor structure, which is subjected to a load perpendicular to the fibre, the connection system must ensure the proper flow of forces through the floor, effectively "bypassing" it.

Timber columns are lighter and more flexible, reducing the overall weight of the structure and making it easier to adapt to seismic or lateral wind forces.

Choosing to develop the floors in CLT is a way of further lightening the structures.

Benefits of timber post-and-slab systems:

Lightness and reduced loads on foundations

Timber's lower specific weight compared to materials like concrete and steel reduces the loads on foundations when used as the primary construction material, resulting in cost savings on excavation and foundation works.

Ease of assembly

The components can be prefabricated with high precision at the production plant and then rapidly assembled on site, thereby cutting construction times and costs while improving the overall efficiency of the project.

Seismic strength

Choosing a material like CLT improves the seismic strength of post-and-slab structures, ensuring the safety of buildings in areas with a high earthquake risk.

Flexible design

Post-and-slab structures that utilise appropriate connection systems allow for large spaces without the need for intermediate load-bearing walls, offering greater flexibility when it comes to future renovations and interior customisations.

Problems with floors in CLT

Stiffness of floors with wide column spacing

Ambitious designers are frequently faced with the problem of developing floors in CLT that are stiff enough to support wide column spacing, a coveted design feature, particularly in multi-storey and public buildings. Since timber floors tend to be quite light, they are prone to issues related to excessive deformation and vibration (service limit states). Careful design is thus essential in avoiding these problems.

Transport

Large CLT floors imply large flat timber surfaces. Transporting such large elements to the construction site to develop stylish open spaces requires specialised means and, therefore, higher expenses.

So, to optimise transport costs, panels are typically chosen in sizes compatible with standard vehicles (12m x 2.9m). What this means, however, is that the panels will need to be joined directly at the construction site.

Applications of post-and-slab technology

The post-and-slab system is well-suited for residential, commercial and public buildings, combining the look of timber with the strength of concrete to create safe, lasting and visually appealing spaces. It is also an excellent choice for buildings in earthquake zones.

Is concrete the future of CLT?

Those who work with this material are familiar with the problems involved in designing floors in CLT characterised by wide spacing between the load-bearing columns. This approach requires transporting primarily moderate-width panels (normally 3.5 m), which can then be stiffly joined on-site using plates and epoxy resins.

However, this solution, although structurally viable, requires high-level accuracy and control, and in many countries, not only is on-site gluing not recommended, it is also forbidden.

The advantages of a hybrid system

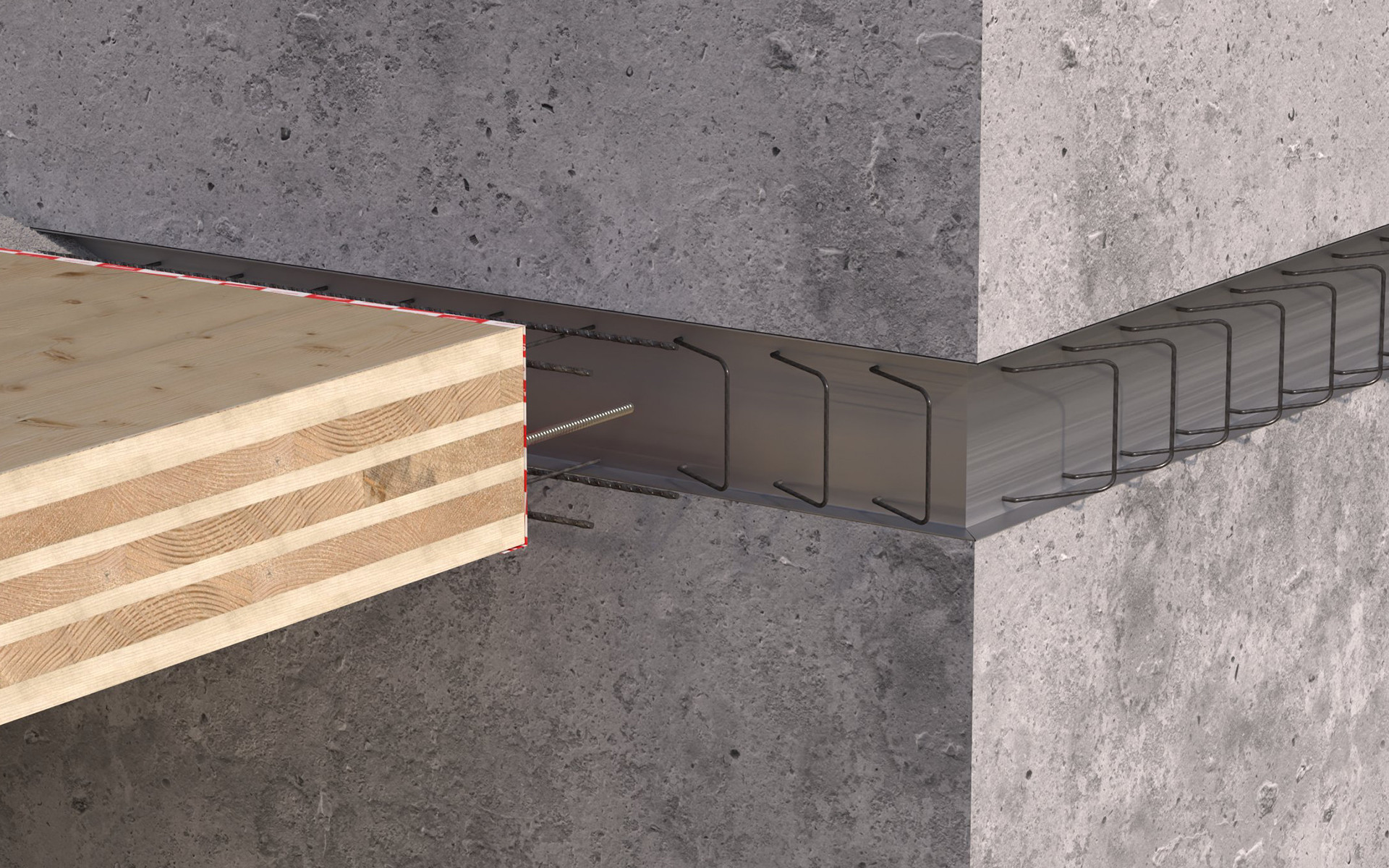

The Rothoblaas TC FUSION system allows panels to be joined no longer by gluing, but by a timber-to-concrete-to-timber connection. Given the stiffness of reinforced concrete, floors developed as such are particularly resistant to deformation and vibrations, allowing a greater distance between columns compared to the standard 6 m.

Best results are obtained when TC FUSION is combined with a collaborating slab, which improves the floor's performance by creating a “composite section”. Using CTC, the concrete slab can be connected to the timber, improving its overall performance.

Following the development of the SPIDER and PILLAR systems, TC FUSION represents the missing piece: a connection capable of restoring structural continuity between CLT panels.

Individual CLT panels can therefore be transported to the construction site using standard vehicles, and then joined to form a single monolithic panel of virtually any size through partial interlocking.

Managing large loads and connections: therein lies the solution for building floors in concrete and timber.

The SPIDER system by Rothoblaas was developed with the aim of creating connections between columns and floors capable of bearing great loads, allowing taller constructions and reducing the number of columns to a minimum.

Thanks to the collaboration between Prof. Roland Maderebner from the University of Innsbruck and Rothoblaas technical staff, TC FUSION now provides a comprehensive system that also meets the need for large floor panels.

The technology on which TC FUSION is based is actually very simple, reliable and well known to engineers, essentially involving screws and reinforced concrete.

The screws, which are certified for both timber and concrete, are inserted partly in the timber and partly in the reinforced concrete, allowing the stresses to be transferred between the two materials. The reinforced concrete kerb is therefore only a bypass or, rather, an intermediate element inserted between the CLT panels to perfectly transfer the stresses.

Applications of TC Fusion: not just floors

TC FUSION finds its place not only in floors, but in a multitude of situations where a CLT panel must be stiffly connected to a reinforced concrete element.

For example, it is possible to create the support of a CLT floor on a reinforced concrete wall, or to use the system to connect timber walls to the ground or to connect timber walls to a reinforced concrete wall.

TC FUSION combines the simplicity and precision of timber construction with the tolerances typical of reinforced concrete construction, thereby addressing the issue of discontinuity between CLT panels and making it easier to transport them to the construction site.

With TC FUSION, a combination of screws and structural reinforcement bars capable of joining hybrid structures, prefabricated elements and post-and-slab systems, is finally available. The new timber-to-concrete jointing system is CE marked according to ETA-22/0806.

Read up on all the features in the technical data sheet.

All rights reserved

Technical Details

- Companies:

- HOLZBAU LAYH; BANKWITZ beraten planen bauen GmbH; Raadschelders Bouwadvies ;JM Concepten B.V.

- Country:

- Any

- Продукция:

- TC FUSION SPIDER PILLAR CTC