Fire resistance in buildings

Fire safety is an essential consideration in the design and construction of buildings, regardless of the materials used.

Every type of structure – whether concrete, steel, timber or masonry – must comply with current regulations and take account of its intended use, with the aim of:

Reducing the likelihood of a fire occurring

Ensuring structural stability during a fire

Limiting the spread of flames and smoke both within the building and to neighbouring structures

Protecting the safety of occupants and facilitating rescue operations

Fire and timber: is the fire resistance of a timber structure inferior to others?

No, the fire resistance of a timber structure is not inferior to that of other materials. In the event of a fire, engineered timber exhibits highly predictable behaviour, dispelling the misconception that timber buildings inherently lack fire resistance.

As with any other construction material, integrating preventive and protective measures into the design is key.

Fire Prevention: active and passive protection

Fire prevention involves a combination of measures designed to prevent, detect and mitigate fire risks. These measures fall into two main categories:

Active protection

Measures that require human intervention or the activation of devices, such as:

Alarm systems.

Fire extinguishers.

Automatic sprinkler systems.

Passive protection

Passive protection involves measures that do not require external intervention. These are design strategies based on the chemical and physical properties of materials as well as the construction characteristics. Examples include:

Fire-resistant walls and floors.

Insulating materials.

Fire compartmentalisation.

Fire resistance: definition and ratings

Fire resistance refers to the ability of a construction element to maintain its structural stability during a fire for a certain period of time, preserving compartmentalisation from smoke and hot gases.

Fire resistance ratings

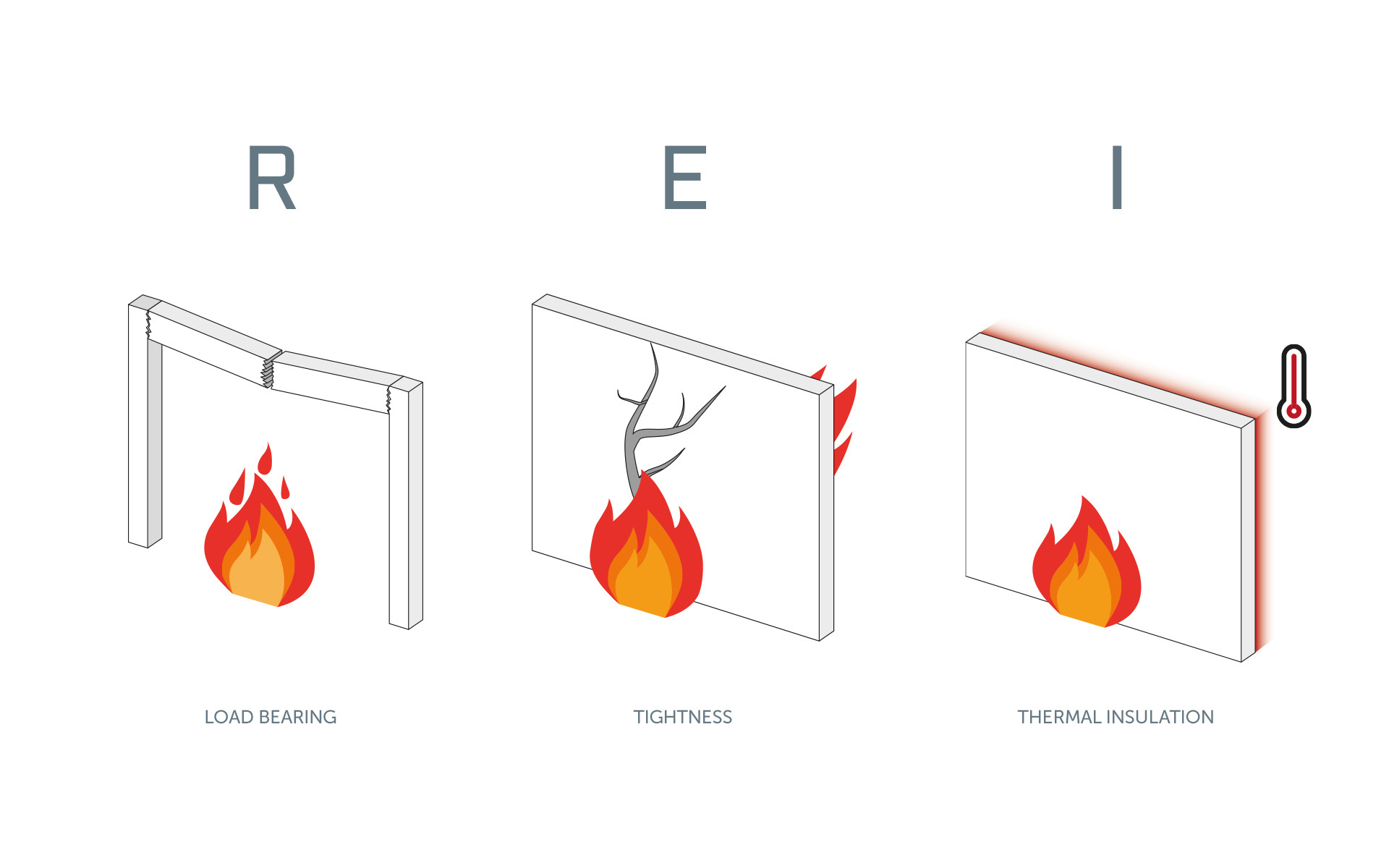

The fire resistance of a structure is defined by three key indicators:

R (Load-bearing capacity): the structure maintains stability under fire conditions.

E (Integrity): prevents the passage of flames, vapours and hot gases to the unexposed side.

I (Thermal insulation): limits heat transfer, keeping the temperature on the unexposed side below 180°C.

Fire resistance ratings are expressed in minutes: 15, 30, 60, 90, 120, 180, 240 and 360 minutes. These values are denoted by the acronym REI (e.g. REI120). For non-load bearing elements, the rating is indicated as EI (e.g. EI90).

The London and Valencia fires: lessons in safety

Two tragic European fires have highlighted the devastating consequences of using inappropriate materials: the Grenfell Tower fire in London and the fire that engulfed two skyscrapers in Valencia. Both cases underscore the critical importance of selecting fire-resistant materials in building design.

The inquiry into the Grenfell Tower disaster (full report available at www.grenfelltowerinquiry.org.uk/) revealed that the rapid spread of the fire was partly due to the use of Aluminium Composite Material (ACM) panels with a polyethylene core. The latter is highly combustible, significantly contributing to the fast progression of the flames. Additionally, ventilated façades amplified the spread of the fire by allowing the passage of hot smoke and gases.

In February 2024, a fire devastated two skyscrapers in Valencia, presenting similar dynamics. Here too, unsuitable materials accelerated the spread of the flames, leading to catastrophic consequences for both the structures and their occupants.

These events highlight the urgent need to prioritise materials with a certified reaction to fire, designed to limit the spread of flames and safeguard both people and buildings.

What is reaction to fire in materials?

Reaction to fire assesses how much a material contributes to the spread of a fire. According to EN 13501-1, materials are classified as:

Class A: non-combustible.

Classes B, C, D, E: combustible, with increasing levels of contribution to fire.

Class F: indicates materials with Non-Determined Performance (NDP) or that do not reach Class E.

Additional parameters assess:

Smoke density: s1 (low), s2 (medium), s3 (high).

Droplet behaviour: d0 (no burning droplets), d1, d2.

Here is a clear example of varying reactions to fire and droplet behaviour:

Fire resistance: design and materials

To ensure structural safety and protect occupants, passive protection measures must be integrated during the design phase. The choice of materials and construction solutions is critical, not only for compliance with regulations but also to provide adequate protection for people and buildings.

Fire resistance is a key consideration in the design of solid timber buildings. For this reason, alongside our range of membranes for the protection of walls, roofs and floors – designed with a reaction to fire defined in line with current standards – we have introduced a new line of products for fire penetrations. These are specifically engineered to maintain the integrity of separating elements in service openings.

All rights reserved

Technical Details

- Companies:

- any

- Country:

- Any

- Продукция: